Thin film pressure sensors are made up of very thin layer which is used to measure the amount of pressure was there. The Thin Film part of the name refers to just how thin the layer is that goes into making these sensors — they literally are THIN as a human hair. They can change pressure into data that people could use the same way they might measure and monitor various other work or task-related pressures. This makes them useful in many domains.

It is difficult to count the applications of thin film pressure sensors in various industry segments, specifically but not limited pregnancy tests (which uses LF of nitrocellulose), and high-pressured liquids or gas systems. They are used, for example in the manufacture of products we use made in factories; designing cars and airplanes to fly through air safely or even medical devices that help doctors and nurses take care of patients. Arguably the biggest factor that people rely on utilizing these sensors is because they are incredibly accurate, able to discern even slight variations in pressure which then can dictate whether or not a product will perform and if safe.

Another that can be cushioned is the crowds of feeling for sensing area on mounting part shape The sensing element need to be small enough not only to fit your desired location, but also larger sufficient that the surrounding pressure changes may get tested properly. In addition, designers must wonder how they will integrate the sensor into a broader system, whether that application is as simple as a pressure switch or more complex using multiple sensors to operate together.

The applications of thin film pressure sensors are vast and can be used in many industries. You will find these in the automotive industry, oil and gas fields all around the world to industrial manufacturing plants. Sensors of this type are essential components of electronic systems, and as examples

Apart from the described applications thin film pressure sensors are also common in medical devices. They keep track of significant health markers such is blood pressure, oxygen levels in the blood and other key physiological measurements. They are also used in space research (where the weight and size of a sensor play an important role) allowing precise measurements to be made even under difficult conditions.

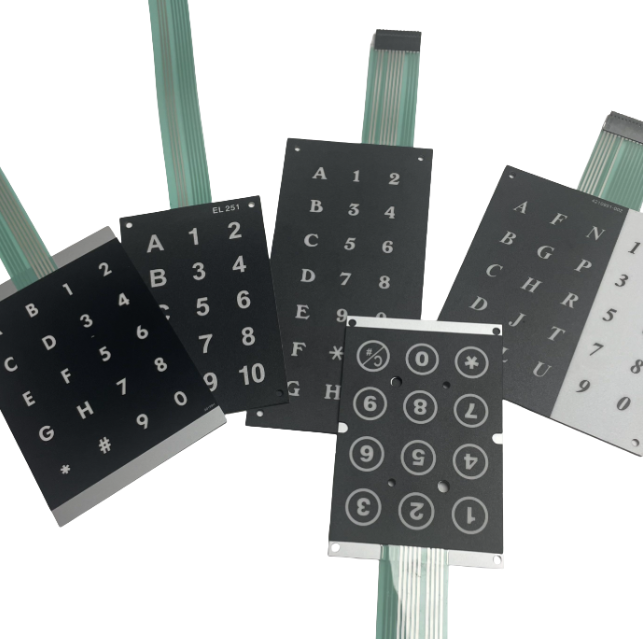

As a technical leader with over two decades of experience, we specialize in the integrated design, R&D, and manufacturing of precision membrane switches and FSR sensors for demanding industries such as automotive, medical, and industrial controls.

With an in-house factory equipped with 300 devices and 4 production lines, we maintain full control over the entire process—from design to delivery—enabling fast customization and accelerated project timelines for clients worldwide.

Our factory adheres to strict standards, certified under ISO9001:2015, RoHS, and the ZHB Environment System, ensuring that all products meet rigorous quality, safety, and environmental requirements.

Benefit from our 24/7 online customer service, with guaranteed response within 8 hours and continuous tracking until goods are received, ensuring swift project support and reliable after-sales solutions.

Copyright © Dongguan Soushine Industry Co.,Ltd. All Rights Reserved - Privacy Policy