Force resistors use the property of some materials that change their capacitance when they are pressed down or pulled. To do this, it needs to know how much pressure is being applied (how HARD the blood was squeezed). Most of the same type (Force) can provide accurate measurement for a variety of quantities, as in weighing grave objects or determine how hard inclining something, such as an exercise hand grip used to measure force expended by the body.

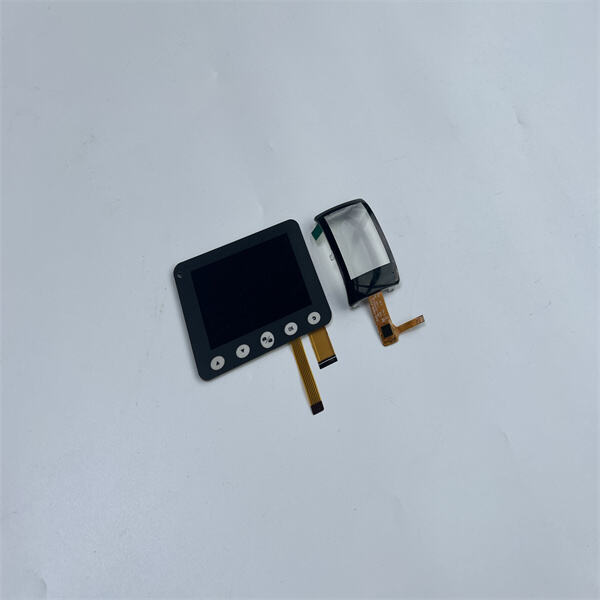

There are other ways that each of the different types of force resistors can function slightly differently, but they all imply a basic idea. Inside the Soushine Flexible pressure sensor is a special material, which responds to pressure. For instance, a force resistor has a strip of metal that deforms when pressure is applied to it, effectively changing its characteristics.

The resistance has a small electric current sent through it, and the module measure how much of that electricity returns. When pressure is exerted on the material, it acts to impede electrical flow and less electricity returns. The sensor uses this change in electricity flow to understand how much pressure/weight is being applied his sensors.

Application Of Force Resistance: These are typical of those used within factories either for receiving or shipping goods, weigh heavy article weights properly and detecting any damage to the machines which may be limited due before they get out of hand. As one example, if a machine is being worked too hard, the Soushine Thin film pressure sensor could help pick that up so repairs can be made before something snaps. And they can be used in medical devices to determine how hard a person is squeezing some grip. It can also let doctors know if there's an issue, such as arthritis (which affects many fibromyalgia sufferers), by measuring grip strength.

You must also consider the material of construction for your resistor. You want to choose a material that will be able to take and release the right amount of pressure from whatever ammunition you are using. The resistor you choose has to be dependable and long-lasting, otherwise a miscalculation can bring disastrous consequences. If not, a sensor will pass false numbers to you and those could mean errors in whatever you want to measure/control.

And speaking of preparing to force resist, you need some way to measure differences in applied forces. And when measuring with a Soushine Pressure sensor it is important that they are functioning as expected and reporting real changes effectively. That process is regarded as calibration. Calibration is an important process to make sure the results are good from that, they must be accurate and consistent.

Lastly, known forces should be used to apply them on the sensor during calibration. This can be achieved using weights or a manipulation device designed specifically for this purpose. You can calibrate the sensor by applying different weights to make sure that values read are accurate for a variety of pressures or weight. This is very important to ensure that everything goes correctly as desirable.

Benefit from our 24/7 online customer service, with guaranteed response within 8 hours and continuous tracking until goods are received, ensuring swift project support and reliable after-sales solutions.

As a technical leader with over two decades of experience, we specialize in the integrated design, R&D, and manufacturing of precision membrane switches and FSR sensors for demanding industries such as automotive, medical, and industrial controls.

Our factory adheres to strict standards, certified under ISO9001:2015, RoHS, and the ZHB Environment System, ensuring that all products meet rigorous quality, safety, and environmental requirements.

With an in-house factory equipped with 300 devices and 4 production lines, we maintain full control over the entire process—from design to delivery—enabling fast customization and accelerated project timelines for clients worldwide.

Copyright © Dongguan Soushine Industry Co.,Ltd. All Rights Reserved - Privacy Policy