Flex sensors play a key role in numerous electronic devices and projects. They can sense bending and flexing, and using nodes such as these you have the ability to drive other parts of your device. While, there are numerous different flex sensors to be had however how do you decide the proper one on your undertaking. This post will address some of the important parameters to look at when selecting a Soushine flex sensor including length, resistance and type.

Length is the key to the Flex Sensor

The length of a flex sensor is the distance of bend from one end to another. The flexibility of the sensor also plays an important role in how far it is allowed to bend before it starts malfunctioning. The longer it is, the better you can bend it (if you need high-angle bends, take a long one). For a sensor that only needs to bend slightly, on the other hand, you might be better off with a shorter one.

Select the Right Resistance Value For Your Flex Sensor

When deciding on a flex sensor, the resistance also features prominently. Resistance is the level of obduracy that exists to the flow of electricity through a sensor. Bending forces will bends the flex sensor more or less depending on how much resistance it provides. You need to select the appropriate resistance for a flex sensor for your project, otherwise, it will not able to function correctly.

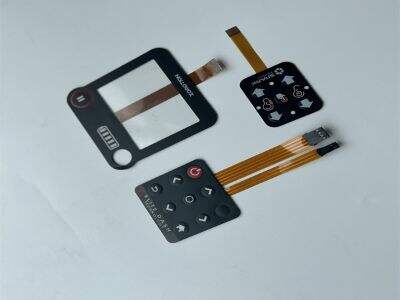

A Comparison of Different Types of Flex Sensors

Flex sensors comes in all shapes and sizes, and each has its own pros and cons. Some other more flexible, some more resistant. 5. There are also sensors built especially for a single application like in medical devices or robotics, etc. It's vital to choose the right flex sensor according to your project and use case but which one is right for you?

Select the right Flex Sensor with these key points

Key Aspects to Select a Flex Sensor These include sensor length, resistance level and the type of sensor. You may also need to consider where the sensor is going to be used, since some sensors could more liquid resistant or more temperature stable than others. A wide variety of factors are reviewed here to help you make the most appropriate choice in a Soushine Thin film pressure sensor for your specific project.

Choosing The Correct Flex Sensor For Your Application

The particular use of your project helps you determine the flex sensor to choose. Consider how much the sensor will flex, how hard it will be pressed on, and what environment you are using the hand in. You also might consider looking up reviews or asking people who have used flex sensors on similar projects. When you choose a flex sensor, remember to take your time and pick the appropriate device for your project, so that it functions well and also has consistency.

To summarize, to have a successful application you must select the correct flex sensor. You need to take into account length, resistance, type of sensor and what are you going use the temperature sensor for before you buy one. An accurate and durable flex sensor lends itself quite well to real-world electronic devices or projects. This is why we recommend you to choose the best Flexible pressure sensor according to your needs and start making something cool with Soushine.