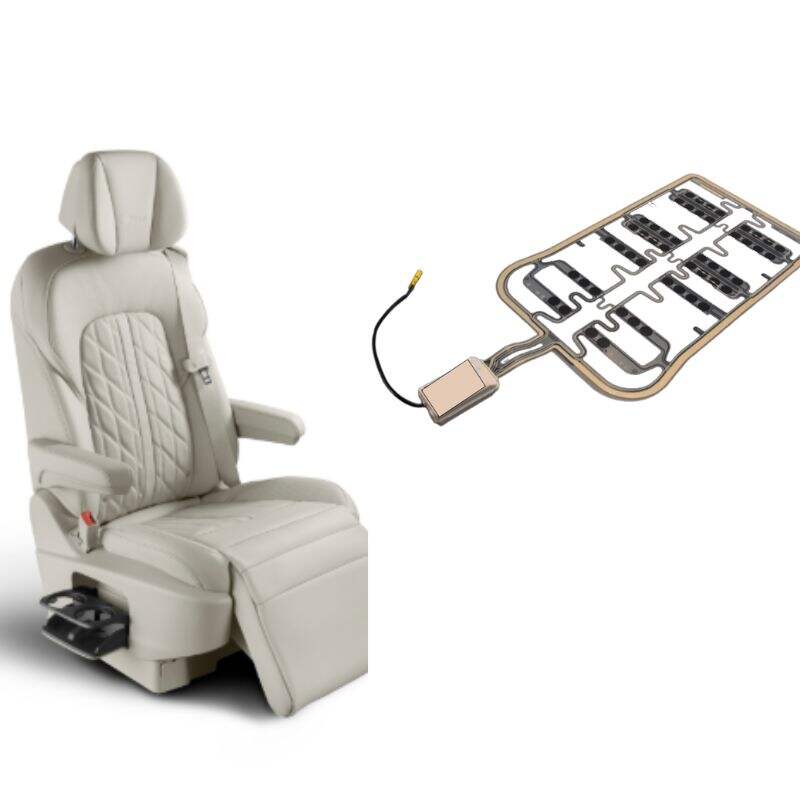

Car seat sensors are important because they let the car know if someone is using the seat. This allows the car to know whether to deploy the airbag. If it doesn’t work properly, the sensor could fail to protect someone sitting in that seat. It is very important to test these sensors, ensure they work well. When you test them, you’re trying to see if the sensor responds precisely when someone sits in or gets out of a chair. At other times, sensors can be oversensitive or not responsive enough. This is something you want to learn early not late it will save heartache. And it not just whether the sensor functions, but whether it continues to function after repeated uses. So, looking at accuracy and how long the sensor will last is a smart move.

Where Can I Get Wholesales Car Seat Sensors that are Accurate?

The problem is it is difficult to locate a legitimate source to purchase car seat sensors in bulk. It’s sensors that work each time, you see, and fail not too easy. At Soushine, our car seat sensors have thorough tests done on them before it is made available in the market to be purchased. The reason behind this is that they are tested on the ability to detect the pressure points accurately and also the speed at which they can be activated. Think of purchasing a pack of sensors to the seats you are sitting in your car you do not want to crash on some of them after a couple of times of using them. Soushine Car seat sensor are designed to be long lasting and precise in terms of use. When purchasing wholesale sensors, you will want to make sure that the sensors are tested under various conditions such as hot or cold climate. The sensors can work differently in case it is freezing outside or it is extremely hot in the car. Another factor to keep in mind is the sensor should fit well in the seat. If it’s too large or small, the fit might not be right. Soushine’s group takes the time to get these details and collaborates with customers in finding the actual right sensor. There are sellers who give a damn only about selling as many sensors as possible in the shortest amount of time but Soushine cares about safety and high-end quality for their customers. Ask to see evidence that the sensors have been used in practice in the real world not only on paper before buying. This evidence may be reports or video testing. Extended warranty should also be offered to great sensors. When anything went wrong, you would want to know that you have someone close by. Then, in case of many car seat sensors, take into consideration how Soushine makes sure that all and every sensor will be ready to keep people safe in their cars.

How to Troubleshoot the Most Common Car Seat Sensor Problems on Bulk Orders

You should be taught at an early age how to identify problems when buying numerous car seat sensors. In some uncommon situations, sensors may seem to be functional but have hidden issues which manifest themselves in the future. False signal may be the result of the sensor, which is a widespread issue. This is to say that it is reporting someone sitting down when nobody is there, or it is not seeing anyone sitting down. This is dangerous because such faults may cause the airbags to go off either not at all or at all. In order to detect these ills, you may examine whether the sensors are operating properly or not by placing various weight on them light things, heavy things, zero weight. When the sensor works the same way, then it is likely that it is operating well. One of the similar problems could be the fact that sensors break down with time because of the way they are constructed, or they are installed. They run water in streams and shake hard things can be broken. To check whether the sensors react to tiny portions of water or vibrations. Sensors made by Soushine pass such tests to make sure that they can withstand strenuous conditions. Buying them by large quantities, store a sample of sensors in each batch and test them after some period of time. Then, should some sensors malfunction or fail, you do it early enough and you will not put bad sensors on a large number of cars. Sometimes an error can occur in wiring or the method upon which the sensor interacts with the car system. One way that you can save time is by checking on your wires and plugs before installing them. In case anything seems loose, or broken, fix the problem to enable sensor could be used. It is time consuming to test sensors individually, though it is preferable to the alternative of pulling out the hair and borrowing money in the future. The chances of problems with Soushine sensors are minimal as the products are made more exactly in addition to being well tested to prevent these repeatability problems. Real-time monitoring of sensor failures makes it easy to remain safe and make sure that the drivers and passengers are safe at all times.

What Tools Are Required to Test Car Seat Sensors in Wholesale Quality Control

How to Test Car Seat Sensors for Wholesale Price Matters It’s important to have the tools necessary for quality assurance in place when you are testing car seat sensors. Sensors in car seats can sense if a body is sitting in the seat, for example, triggering safety features like airbags. If these sensors fail to detect properly, it can create safety issues. At Soushine, we emphasize the low-cost but efficient tools to test all sensors before shipping from factory.

First up, a digital multi-meter is a must. This measures electrical signals to test if the sensor is transmitting the correct signals when pressure is applied. The multi-meter tells if the electrical components of the sensor are functioning or if there are any disconnects in the wires. Second, you will need a pressure simulator or a wrist scale. This device applies a controlled pressure or load to the sensor and simulates that there is someone in fact sitting on the seat. This is to test if the sensor can in fact correctly detect different weights.

Another are a computer or a testing-device with special software. This program downloads the data transmitted by the sensor and determines if is correct. It can save the response time of sensor and test whether the sensor is working or not. For large orders, the software can test multiple sensors at the same time, saving time and assuring each sensor meets quality standards.

Finally, a basic manual checklist is nice to have as well. This checklist helps the tester to verify each crucial aspect of the sensor. With these two tools combined, Soushine can be sure that every car seat sensor is tested thoroughly before it reaches the customers. This also helps ensure the sensors are accurate and reliable which is especially important for keeping drivers and passengers safe.

How To Guarantee Car Seat Sensor Accuracy When Sourcing In Large Quantities For Automotive Manufacturing

If you are purchasing a large quantity of car seat sensor for the auto manufacturing industry, it cannot be stressed enough to verify every sensor is correct. Accuracy refers to the sensor’s ability to accurately identify when someone is in a seat and send the appropriate signal to the car’s safety system. Here at Soushine, one of our most important priorities is accuracy because safety relies on it.

How to obtain true performance First and foremost, request the supplier information about how the sensors were tested before they shipped. "WAV MDL"contains documents such as sensor performance tests, quality control procedures and certificates among others. Such documents indicate whether the sensors meet the safety rules and standards of industry. It’s also valuable to know how the sensors respond to various weights and pressures, so they will be effective for people of all sizes.

And then what you do is, when the sensors come in, it’s smart to sort of test your own samples. This involves the testing of a small number of sensors, from the toner, during and after production to ensure their fitness. At Soushine, we have special testing machines to apply weight and measure the response of the sensor. If the sensors pass these inspection steps, that would mean I probably have a good batch.

Is it helpful to also have clear quality standards in place before making the purchase. That involves imposing limits on things like how fast the sensor has to respond and how much mass it must identify. If a sensor does not fall within these limits, it should be thrown out or repaired. By setting a high bar for such tests, car seats are kept safe.

Finally it helps a lot if you are working with a good supplier like Soushine. We’re never going to want sensors that aren’t accurate or that don’t work. We also offer help and tips for testing sensors. This partnership plays a key role in ensuring that automotive makers receive the highest-performing sensors for their car seats to ensure driver and passenger safety on every drive.

Performing Rapid and Effective Car Seat Sensor Tests for Bulk Orders

Time is of the essence when checking car seat sensors for a big order. You want to check many sensors in a short time, but also be sure that each sensor is working properly. At Soushine, we’ve learned to do rapid and sensitive testing that allows quality standards to remain high without impeding production.

The first is automation testing tools. These machines can simultaneously test many sensors. They put pressure or weight on the sensor and record how it responds. Because machines are doing this work, the tests run quickly and can be repeated many times without error. Using machines lets us be confident that each sensor was tested the same way, which is very important for fairness and accuracy.

And then, write a simple test plan. This plan details precisely what to test, and how to test it quickly. Testers need to verify whether the sensor also responds to light, medium, and severe force for instance. They also need to record the speed at which the sensor processes a signal. A clear plan ensures that testers can work fast, without skipping any important steps.

Another useful idea is to conduct random spot checks. This involves physically inspecting a sort of subset of sensors more closely, by hand or with additional tools. Spot checks help to detect any problems the machines might miss; if an issue is discovered, it can be rechecked or fixed in its entirety before shipping.

Finally, good record-keeping is important. Record the test results and use them to monitor any issues. This has helped identify patterns and improve future testing. At Soushine, we have some software to save test data and to generate reports. That way, we can always be confident about how well our sensors work, even when testing thousands of them.

With these methods, Soushine can test large quantities of the car seat sensors rapidly and securely. This gets automotive manufacturers safe, precise sensors on their vehicles when they need them and keeps drivers and passengers safe every day.

Table of Contents

- Where Can I Get Wholesales Car Seat Sensors that are Accurate?

- How to Troubleshoot the Most Common Car Seat Sensor Problems on Bulk Orders

- What Tools Are Required to Test Car Seat Sensors in Wholesale Quality Control

- How To Guarantee Car Seat Sensor Accuracy When Sourcing In Large Quantities For Automotive Manufacturing

- Performing Rapid and Effective Car Seat Sensor Tests for Bulk Orders